Do you love the sound of high-performance engines and the precision of fast machines?

If the answer is yes, and you dream of building or repairing race cars, becoming a motorsports welder might be the path for you.

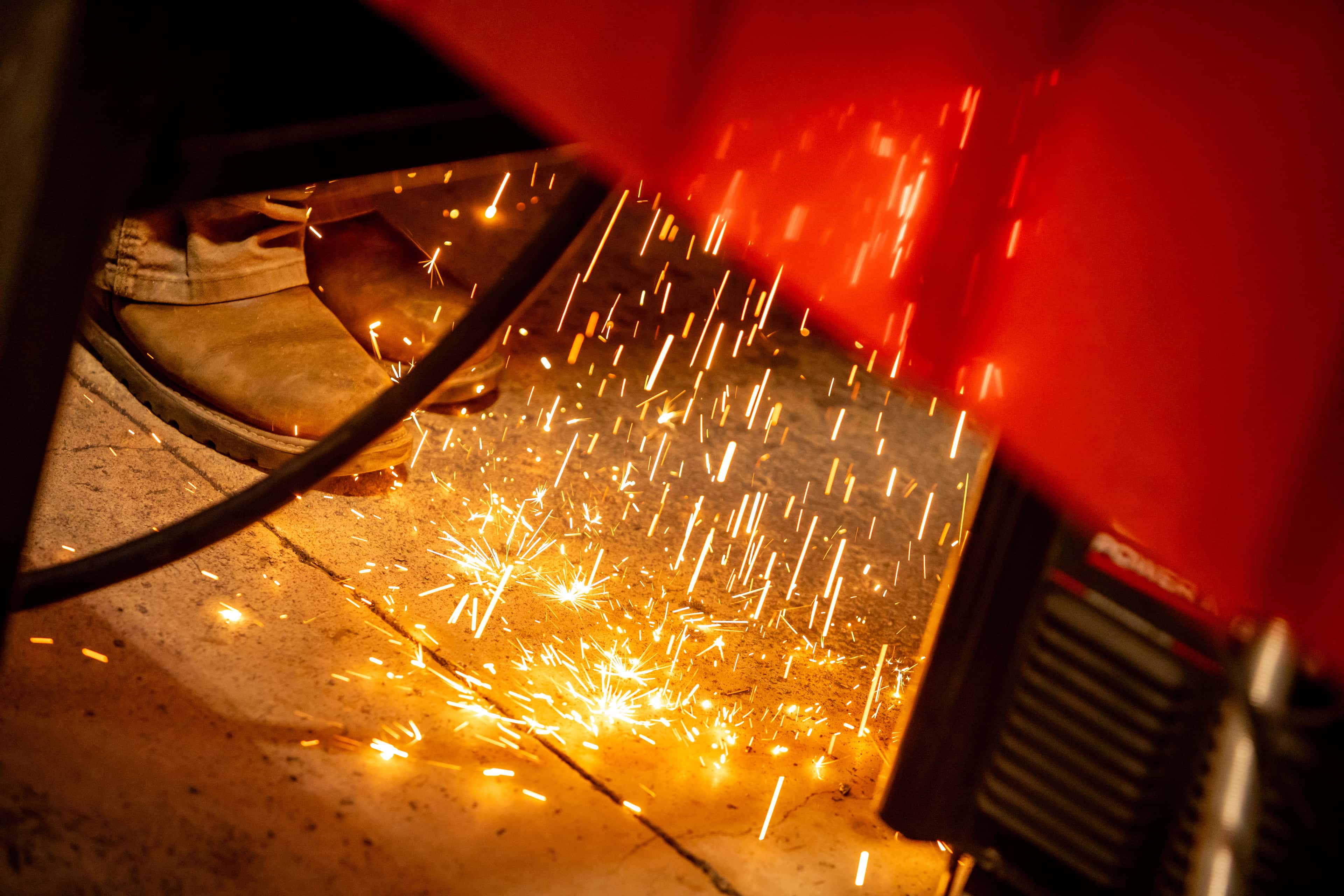

From drag racing to track days, skilled welders are needed behind the scenes to help ensure vehicles are race-ready. With the right training, tools, and techniques, you could be on the path to pursuing a hands-on career in competitive motorsports.

Keep reading to learn more! You can learn what this role involves, what skills you'd need and how hands-on, Welding Technology training from Universal Technical Institute can help you prepare to get there.1

What is a Motorsports Welder?

A motorsports welder is a fabrication professional who builds, repairs or customizes race cars, performance vehicles or parts used in high-speed automotive applications. These welders use precise techniques to construct or modify key components like roll cages, suspension parts, exhaust systems and chassis frames.

Safety, strength and accuracy are critical in this line of work, especially because parts must withstand extreme forces at high speeds.

How Motorsports Welding Fits Into Automotive Fabrication

In racing, every detail matters. That includes how a car is built.

Welders support race teams by helping fabricate vehicle frames, modify engine compartments or reinforce safety structures. Because motorsports welding can directly impact a car’s performance and structural integrity, welders in this field must know how to apply proper welds to specific materials without adding unnecessary weight or stress.

Skills and Tools Needed for Motorsports Welding

Motorsports welders need a strong understanding of welding techniques, materials, and fabrication processes. Many of these skills are taught in pro career training programs like UTI’s Welding Technology program.

If you’re interested in learning the foundations of welding, UTI’s Welding Technology program may be right for you. This program prepares graduates for entry-level roles like welder, fabrication welder, welder fitter, and wirer.77

TIG welding for race cars

Tungsten inert gas (TIG) welding is commonly used in race car fabrication because it allows for greater control and produces clean, strong welds. It works well with thinner materials like aluminum and is often used for chassis, suspension and custom exhaust systems.

MIG welding for speed and efficiency

MIG (metal inert gas) welding is a faster technique often used for thicker materials or when quick repairs are needed. It’s a go-to option in motorsports settings where time and strength matter, especially during builds and between races.

Flux-cored arc welding in motorsports

Flux-cored arc welding is similar to MIG but uses a tubular wire filled with flux instead of solid wire and shielding gas. It performs well outdoors and in drafty environments, making it a solid choice for welding in less controlled conditions around the track or shop.

Stick welding for versatility

Shielded metal arc welding (SMAW), also known as stick welding, is valued for its versatility and ability to work on dirty or rusty surfaces. While less common in high-end race car builds, it’s still used in motorsports for repairs and structural welds when portability and ruggedness are key.

Chassis and frame fabrication

Welders working in motorsports need to understand how to fabricate or reinforce the structural framework of a race car. This includes measuring, cutting and welding steel tubing to meet performance and safety standards.

Working with aluminum and steel

Aluminum is light and corrosion-resistant, while steel is strong and widely used for structural parts. Knowing how to weld both is essential for a career in motorsports fabrication.

Factors That Influence a Career in Motorsports Welding

Your career as a motorsports welder could look different depending on the vehicles you work on, your experience level, and where you’re based.

Work environment (trackside vs. shop)

Some welders work on cars directly at the track, making fast repairs before races. Others work in fabrication shops, where they have access to advanced tools and more time to customize components.

Type of vehicles worked on

From dirt bikes to drag cars, every type of racing vehicle has different welding and fabrication needs. Specialized knowledge of each vehicle’s structure helps welders do the job right.

Level of experience and specialization

As welders gain experience, they may specialize in certain materials or types of fabrication. Employers often look for those who are trained and certified, especially in high-stakes motorsports environments.

Motorsports welders often need certifications from the American Welding Society (AWS) to prove their skills and meet industry standards. Common credentials include the AWS D1.1 for structural steel and AWS D1.2 for aluminum, both of which are materials frequently used in race car fabrication. These certifications help show employers that a welder is qualified to perform precise, high-quality welds under performance and safety demands.

Where to get trained: welding programs for motorsports

To become a motorsports welder, many professionals start by completing a formal training program, like our 9-10 month welding training program. This program covers the core techniques used in motorsports welding, including MIG, TIG and stick welding. Our courses also teach fabrication and blueprint reading, two important skills for motorsports careers that are difficult to learn properly without industry-aligned instruction.

Our welding students get hands-on training and guidance from experienced instructors, helping them build skill sets that qualify them for an entry-level role in the industry after graduation. After that, they can continually build upon their knowledge and advance to potentially lucrative, advanced roles—like motorsports welding.77

Start Your Welding Career Path with UTI

Passionate about cars? Want to take your skills to the next level?

A career in motorsports welding might be a great fit. Whether you're interested in working on race cars or building custom track builds, welding is a key part of the process—and these specialized pros are in demand.

Call an Admissions Representative today at 1-800-834-7308 to ask questions or learn more about how UTI’s Welding Technology program can support your journey toward a welding career. If you’re ready to start your journey, click here to apply!

Universal Technical Institute of Illinois, Inc. is approved by the Division of Private Business and Vocational Schools of the Illinois Board of Higher Education.