Are you considering pursuing a hands-on, high-paying technical career? Becoming a certified non-destructive testing (NDT) technician in 2025 could be the game-changer you're looking for. This NDT career guide walks you through everything—from NDT certification levels and NDT technician training to the most in-demand testing methods and how to advance your career through ASNT certification.

What Is Non-Destructive Testing?

Non-destructive testing refers to a variety of inspection methods used to evaluate materials, components or systems without causing any damage. Unlike destructive testing, which can involve breaking or damaging a part to assess its quality, NDT preserves the integrity of the material being tested.

In industries like aerospace, NASCAR, Formula 1 and manufacturing, where safety and performance are critical, NDT plays a vital role in ensuring that parts are up to standard without compromising their function. NDT certification qualifies technicians as properly trained to perform these inspections.

Why Become a Certified NDT Technician in 2025?

Pursuing a career in non-destructive testing can open doors to rewarding jobs, advancement opportunities and diverse industry applications. Here’s why getting your NDT certification in 2025 is a smart move.

Demand for Skilled NDT Professionals

According to the Bureau of Labor Statistics (BLS), there are 5,000+ estimated average annual non-destructive testing technician job openings in the U.S.70 This NDT career guide shows how certified professionals are becoming key players in many different fields, including aerospace, automotive, construction and manufacturing. These technicians help ensure that systems, parts and structures remain safe and reliable, making them crucial for preventing costly failures and improving overall quality.

Higher Salary Potential and Career Advancement

Certified technicians can enjoy higher earning potential and opportunities to move into supervisory or specialist roles. Employers value professionals with ASNT certification and practical NDT technician training.

Meeting Industry and Safety Compliance Standards

Many industries require certified professionals to meet regulatory and safety standards. Obtaining an NDT certification can help ensure you’re fully compliant and ready for high-responsibility roles.

Types of NDT Certifications and Levels

Getting the right NDT certification is essential to building your career in the industry. Certifications are typically structured across three levels:

NDT Level I – Entry-Level Certification

Great for beginners, Level I allows technicians to perform tests under direct supervision. It’s often part of an employer's structured NDT technician training program.

NDT Level II – Intermediate Certification with Hands-On Experience

With this level, technicians can set up equipment, perform inspections and interpret results with minimal supervision.

NDT Level III – Advanced Certification for Experts

Level III certification focuses on leadership roles, such as managing teams, auditing processes and developing testing procedures. While this advanced certification doesn’t involve much fieldwork, it positions you as an expert capable of overseeing and guiding other technicians in the industry. Holding a Level III ASNT certification positions you as a high-level professional.

NDT Methods and Specializations

During your NDT technician training, you will be exposed to various testing methods, each with its advantages depending on the material and purpose. Additionally, at Universal Technical Institute (UTI), we provide training in radiation safety, as required by federal and state regulations—something not all locations offer.

Ultrasonic Testing (UT) – Detecting Internal Flaws

Uses sound waves to find defects in metals and composites—an essential method covered in most NDT training programs.

Radiographic Testing (RT) – X-ray and Gamma-Ray Inspection

This method reveals internal defects using radiation, commonly used in high-stakes fields like aerospace.

Magnetic Particle Testing (MT) – Surface and Near-Surface Defects

Ideal for inspecting ferromagnetic materials and is a standard part of many NDT certification exams.

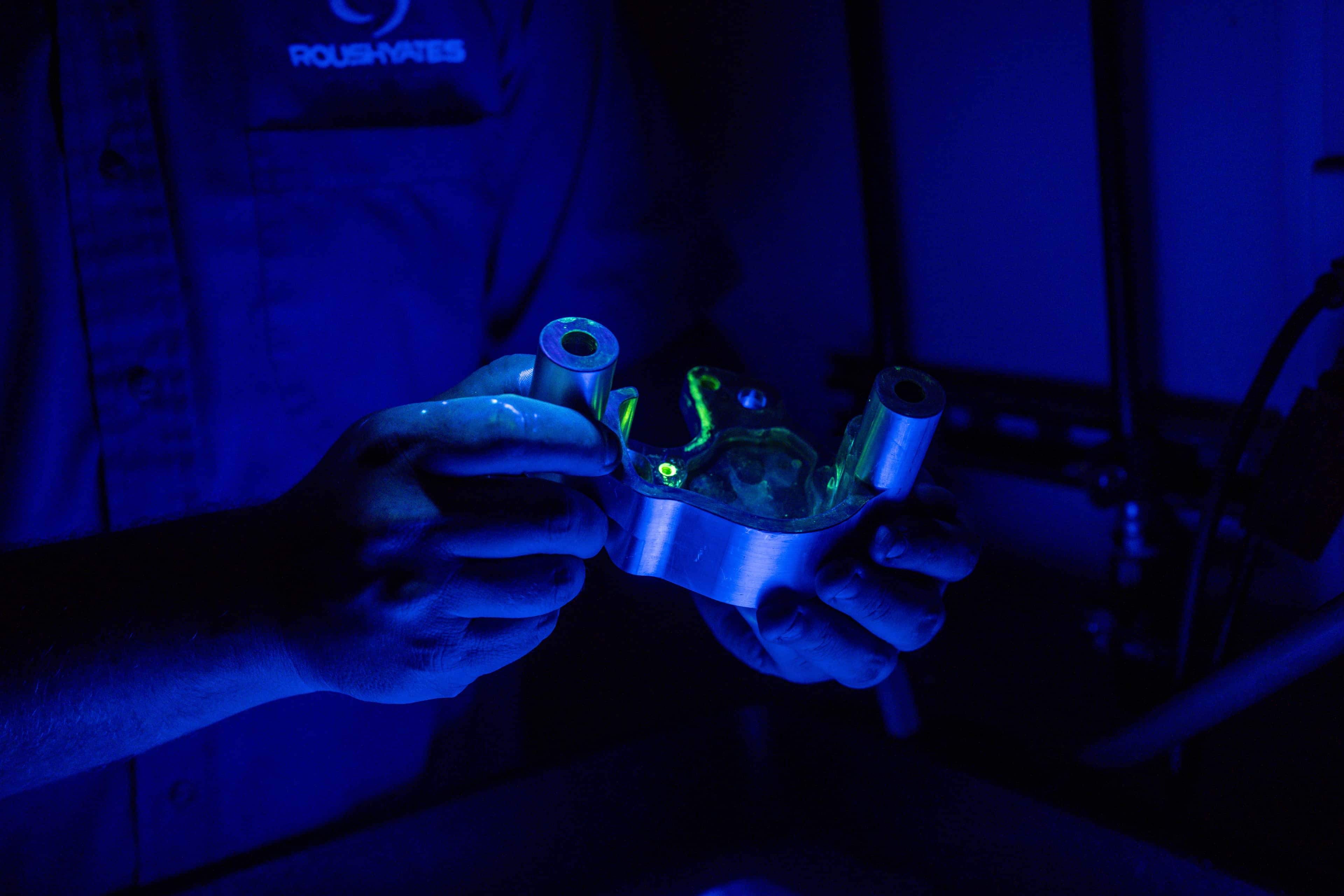

Liquid Penetrant Testing (PT) – Detecting Surface Cracks

This method uses a dye to highlight surface cracks in materials. It's simple but very effective, especially in industries like automotive, construction and aviation, where safety is a top priority.

Eddy Current Testing (ET) – Electrical Conductivity Analysis

Eddy current testing uses magnets to find cracks and measure thickness in metals. It's a very important technique in the aviation industry, where checking materials closely is crucial for safety.

Visual Inspection – Basic but Essential

Visual inspection is the most common and straightforward testing method, where technicians look for visible signs of damage or defects in materials and structures. It’s a critical first step in many industries, including automotive and aerospace.

How To Become a Certified NDT Technician in 2025

Meeting Eligibility Requirements (Education and Experience)

To begin your journey toward NDT certification, most training programs require at least a high school diploma or equivalent. While prior experience in a technical or engineering-related field can be helpful, it’s not always necessary—especially if you’re enrolling in a comprehensive training program designed for beginners.

Enrolling in a Reputable NDT Training Program

Choose a program recognized by a certification body like The American Society for Nondestructive Testing (ASNT). These programs provide both theoretical knowledge and practical skills, forming the foundation of your NDT technician training. One option to gain the skills and knowledge you need is the Advanced Non-Destructive Testing Technician program at UTI.1 UTI’s program, offered at the Houston campus, combines classroom instruction with hands-on training. Over the course of nine months, students learn key NDT methods such as ultrasonic, magnetic particle, radiographic, liquid penetrant, visual inspection and eddy current testing, as well as radiation safety—essential areas for industry certification and career readiness.

Hands-On Training and Field Experience

Real-world practice is key to passing exams and becoming confident in your testing abilities. Many NDT career guides recommend logging hours under a certified professional. UTI’s training emphasizes real-world application. The curriculum is designed to give students access to the tools, technology and techniques used in the field. Through simulated inspections and supervised practice, students undergo training that mirrors what technicians encounter on the job, helping build both confidence and competence.

Preparing for and Passing the NDT Certification Exam

To pursue NDT certification, you'll need to demonstrate both written and practical competencies. While UTI’s program sets the foundation for these certifications, it’s important to understand that employers ultimately certify technicians through on-the-job training. UTI’s curriculum meets the minimum training hours required by industry standards, ensuring graduates are equipped with the necessary knowledge and skills. UTI's instructors help reinforce core concepts, safety protocols and exam-readiness strategies, giving grads a solid foundation for certification through organizations like the ASNT. Upon completing the program, you’ll have proof of training to meet employer certification requirements as you pursue a career.

Top NDT Certification Bodies and Training Programs

American Society for Nondestructive Testing (ASNT) Certification

The ASNT certification is the most widely recognized in the U.S. and many parts of the world. UTI’s Advanced Non-Destructive Testing Technician program meets the training requirements of ANSI/ASNT CP-189 and ASNT SNT-TC-1A standards, including:

- SNT-TC-1A – Employer-based certification

- CP-189 – Personnel qualification standards

Choosing the right school can play a key role in setting you up for success in a career.6 This NDT career guide recommends evaluating programs based on industry recognition, scope and your long-term goals.

How To Maintain and Renew Your NDT Certification

Your NDT certification isn’t a one-time achievement. Most credentials require renewal every few years, involving either continuing education, re-examination or verified work experience. Staying current not only helps meet compliance standards but keeps your skills sharp.

Is an NDT Certification Worth It in 2025?

With growing attention to safety and reliability across various industries, there may be increasing opportunities for those with NDT skills.

If you're considering a future in this specialized field, explore UTI’s NDT technician training program. This program offers hands-on education and foundational knowledge to help students prepare for NDT certification. Whether you're new to the field or building on existing skills, UTI’s training can support your path toward opportunities in industries that prioritize safety and quality.

Interested in learning more? Request more info or fill out an application today!

Universal Technical Institute of Illinois, Inc. is approved by the Division of Private Business and Vocational Schools of the Illinois Board of Higher Education.