If you’ve ever watched a factory line move with perfect timing, there’s a system behind that precision — one that’s been programmed to think, react and repeat.

That system is often powered by PLC programming.

Automation is everywhere. It moves parts, checks quality and keeps production flowing around the clock.

But someone has to tell the machines what to do — and that’s where skilled technicians come in. Hands-on PLC technician training can help aspiring pros gain the skills to pursue entry-level roles in this field.

Below, we break down how PLC programming works, where it’s used and how you can start learning the tools of the trade.

What Is PLC Programming?

Definition and role

A programmable logic controller, or PLC, is a digital computer used to control machines. It tells equipment when to start, stop or adjust by reading data from sensors and sending instructions to other parts of the system.

PLCs are tough, made to work in hot, dusty or loud environments where regular computers can’t.

Evolution from relay-based to digital logic systems

Before PLCs, factories used relays — physical switches wired together to control machines. These systems were hard to change and needed lots of space.

Now, plc programming replaces those relays with code. Updates happen faster, systems are easier to test and one small device can handle hundreds of instructions.

Read: Types of Industrial Robots and How They're Used

How PLCs Drive Automation

Reading inputs, executing logic and controlling outputs

PLCs follow a simple loop: read input signals, run the program logic and send output commands.

For example, if a sensor says a part is in place, the PLC tells a robot to move it. Then it repeats the process, constantly checking and updating.

Real-life examples: conveyor belts, robotic arms and more

You can find industrial automation systems in everything from food packaging to automotive assembly. PLCs control:

- Conveyor belts that stop when a product is off-center.

- Robotic arms that weld or assemble parts.

- Temperature controls in energy systems.

- Machines that count, label or sort items.

All of these follow programmed logic — built by someone with the right skills.

Read: Application of Robotics: When, Where and How They’re Used

Key Components of a PLC-Controlled System

CPU, input/output modules and power supply

The CPU is the brain. It holds the program and makes the decisions.

Input modules bring in data (like button presses or sensor readings). Output modules send commands (like turning on a motor). A power supply keeps everything running smoothly.

Human-machine interfaces (HMI) and networking

The HMI is what people use to interact with the system. It could be a touchscreen or display showing system status.

PLCs can also connect to networks, sharing data between machines or with a central system — key for smart factories and advanced industrial automation systems.

Read: The 4 Main Types of Automation Explained

Common PLC Programming Languages

Ladder logic

Ladder logic looks like an old relay diagram. It’s easy to read and is one of the most common ways to write PLC programming code.

Function block diagrams (FBD)

FBD uses graphic blocks to show what each part of the program does. It’s useful for repeating tasks or when systems need to be visualized clearly.

Structured text (ST) and instruction list (IL)

ST is more like traditional coding — written out in simple lines. IL is similar but has a shorter, command-like structure. Both are helpful in complex control tasks.

Read: What Is a Programmable Logic Controller?

Technician’s Role in PLC Automation

Programming, testing and optimization

Technicians build logic, test it in the lab and watch it in action. If something’s not right, they adjust until it works.

A skilled technician makes sure machines follow instructions exactly — so production doesn’t slow down or break.

Troubleshooting and preventive maintenance

When something goes wrong, technicians find the issue. They check sensors, software and power supplies. They also run regular checks to stop problems before they happen.

With good training, techs can reduce downtime and keep industrial automation systems running smoothly.

Read: Industrial Control Systems in Manufacturing

H2: PLC Programming Training

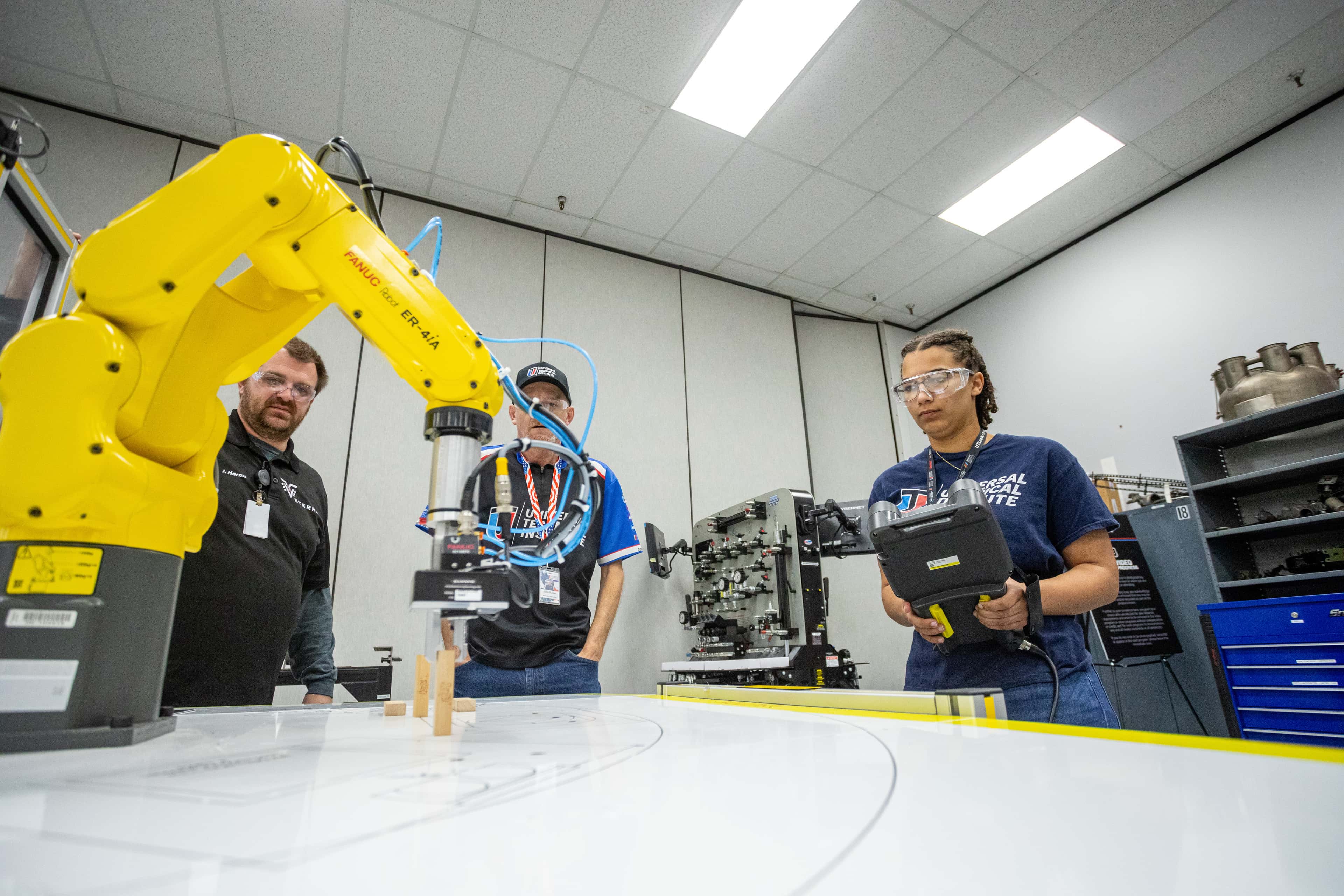

Robotics & Automation students at Universal Technical Institute spend 12-18 months learning core automation skills. As part of this hands-on career training program, students can learn how to write, test and troubleshoot PLC programming code.1

You can practice with real equipment, using the same tools found in hands-on labs and factories. Instructors guide students through projects that simulate what happens in the field — from wiring circuits to building logic for robotic systems.

This is not just about theory — it’s hands-on training with real applications. Graduates are prepared to pursue careers across industries like manufacturing, logistics and energy.

Learn PLC Programming for an Automation Career

The world runs on automation — and behind every working system is someone who knows how to program and maintain it. Robotics & Automation training can teach these skills, including PLC programming, and prepare aspiring technicians to enter an exciting field.

Want to learn more about how to get started? Request info online or call an Admissions Representative at 1-800-834-7308. If you want to get started as soon as possible, enroll now.

Universal Technical Institute of Illinois, Inc. is approved by the Division of Private Business and Vocational Schools of the Illinois Board of Higher Education.