Modern vehicles are powered by software and sensors. Diagnostic scanners let technicians tap into those systems to see what the vehicle is reporting. Automotive diagnostic scanners play a central role in this process by allowing technicians to communicate directly with a vehicle’s onboard systems.

For those interested in learning how today’s vehicles are diagnosed and serviced, Universal Technical Institute (UTI) offers automotive training designed to introduce students to modern vehicle systems and diagnostic tools used in professional settings.1

This guide covers how diagnostic scanners work, the data they read and how technicians use them.

Key Points:

- Automotive diagnostic scanners are communication tools, not repair devices.

- Scanners connect to a vehicle’s onboard computers through a standardized diagnostic port.

- They retrieve data from sensors and control modules across vehicle data networks.

- Diagnostic scanners provide system status, stored information and live data streams.

- Technicians use scanner data alongside inspections and testing to diagnose issues.

- Diagnostic scanners and OBD2 codes are related but serve different purposes.

Why Diagnostic Scanners Are Essential in Vehicles

Cars today are packed with sensors and onboard computers. These systems collect data that technicians use to identify potential issues.

Diagnostic scanners are not shortcut tools or automatic repair devices. Instead, they act as communication bridges between the vehicle and the technician. They allow technicians to “listen” to what the vehicle’s systems are reporting, which helps reduce guesswork and supports more efficient troubleshooting.

As automotive technology continues to advance, diagnostic scanners have become standard equipment in repair shops, dealerships and service centers.

What an Automotive Diagnostic Scanner Is

An automotive diagnostic scanner is an electronic device that connects to a vehicle’s onboard computer systems to retrieve diagnostic information. This connection is typically made through a standardized diagnostic port built into modern vehicles.

It’s important to understand that diagnostic scanners do not repair vehicles on their own. They collect and display information such as system status and sensor data. Technicians must then interpret that information, perform inspections and run tests to identify the root cause of a problem.

How Diagnostic Scanners Communicate With a Vehicle

Diagnostic scanners work by communicating with the vehicle’s internal electronic systems, which include:

- Vehicle sensors that monitor temperature, pressure, speed and other conditions.

- Control modules, such as the engine control module (ECM), transmission control module (TCM) and body control module (BCM).

- Data networks that allow modules to share information, commonly using a controller area network (CAN bus).

When a scanner is connected to the vehicle’s diagnostic port, it sends requests for information across these networks. The vehicle’s control modules respond by transmitting stored data back to the scanner. This exchange allows technicians to see what the vehicle’s systems are detecting in real time or what they’ve recorded in the past.

What Kind of Information Diagnostic Scanners Can Access

Automotive diagnostic scanners can access several categories of vehicle data, including:

- System status that indicates whether certain systems are operating normally.

- Sensor readings that show measurements like engine temperature or airflow.

- Stored and pending issues that signal when systems have detected irregularities.

- Live data streams that update continuously while the vehicle is running.

This information helps technicians build a clearer picture of vehicle behavior before moving on to hands-on testing.

Different Types of Automotive Diagnostic Scanners

Not all diagnostic scanners offer the same capabilities. Tools vary in complexity depending on the technician’s skill level and the type of work being performed.

- Basic code readers retrieve general diagnostic information and are often used for initial checks.

- Professional scan tools provide expanded access to live data, system tests and advanced diagnostics.

- OEM-specific diagnostic tools are designed for particular manufacturers and offer deeper system access.

As technicians gain experience, they typically work with more advanced tools to handle increasingly complex diagnostic tasks.

How Technicians Use Diagnostic Scanners in the Repair Process

Diagnostic scanners are one part of a larger diagnostic workflow. Technicians often follow steps such as:

- Reviewing the customer’s concern.

- Performing an initial scan to gather vehicle data.

- Conducting visual inspections of related components.

- Testing systems and verifying potential issues.

This structured process helps technicians confirm problems before making repairs, supporting accuracy and efficiency.

Diagnostic Scanners vs. OBD2 Codes

Diagnostic scanners and OBD2 codes are closely related but not the same thing.

- Diagnostic scanners are the tools used to retrieve vehicle data.

- OBD2 codes are standardized messages contained within that data.

The scanner collects information, while OBD2 codes represent one part of what the scanner displays. To learn more about how technicians interpret these codes, check out this related guide: OBD2 Codes: A Beginner’s Guide.

Why Learning Diagnostics Is Critical for Future Auto Technicians

Automotive diagnostics play a major role in modern vehicle service. Strong diagnostic skills can help technicians work more efficiently, reduce unnecessary part replacements and meet the expectations of today’s repair shops.

As vehicles continue to integrate more electronic systems, technicians who understand diagnostic tools are better positioned to adapt and grow within the industry.

Why Learning Diagnostics Is Critical for Future Auto Technicians

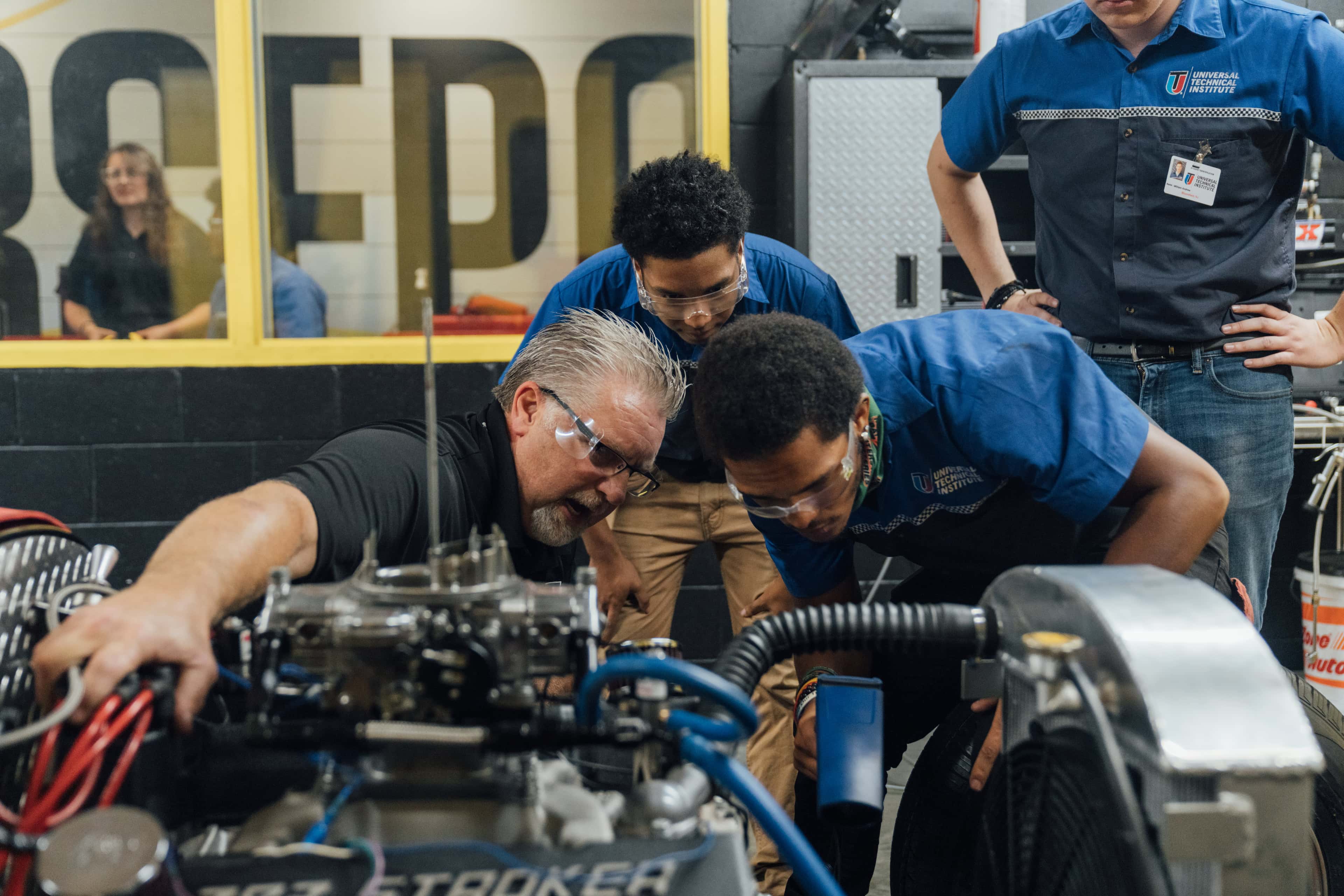

UTI’s Automotive Technology program introduces students to diagnostic scanners as part of hands-on learning.18 Students learn how to connect tools, retrieve vehicle data and understand how scanners fit into a complete diagnostic process.

If you’re interested in building foundational knowledge in automotive diagnostics and learning how technicians use modern vehicle diagnostic tools, you can explore training options and take the next step today by filling out an application!

Sources

Universal Technical Institute of Illinois, Inc. is approved by the Division of Private Business and Vocational Schools of the Illinois Board of Higher Education.