Electricity runs through everything from light switches to large industrial systems. But what helps keep those systems safe and efficient?

The answer: Choosing the right wire size. One of the simplest ways to choose the right wire size is to use a wire gauge chart. Consulting the proper schematics ensures that your wiring matches the amps and loads it’s meant to handle. The wrong choice can mean overheating, wasted energy or even safety hazards.

If you’re curious about how wiring works — and how professionals apply charts, ratings and codes — you’re already thinking like someone in the electrical field. With hands-on training from Universal Technical Institute (UTI), you can go beyond reading charts and start learning the skills used every day in industries like robotics, automation, electronics, wind energy and industrial maintenance.130

Keep reading to learn more about the basics of choosing the right wire for the job like a pro.

What Is AWG?

The American Wire Gauge (AWG) system is the standard way to measure wire size in the U.S. It assigns numbers to wire diameters so electricians and technicians can choose the right one for the job.

How Wire Gauge Numbers Work

Smaller number = thicker wire

In the American Wire Gauge system, the numbering may feel backwards at first. A smaller AWG wire size number actually means a larger-diameter conductor with less resistance. This is why thicker wires can carry more current without overheating.

For example, 10 AWG is noticeably thicker than 14 AWG. Because of this, 10 AWG can handle heavier loads safely, while 14 AWG is better suited for lighter household circuits. Knowing how AWG wire size works helps technicians select the right conductor for the job.

Gauges for household and light commercial circuits

In most homes, 14 AWG and 12 AWG are the standard wire sizes you’ll find in lighting and outlet circuits. Fourteen-gauge wire is typically used for 15-amp circuits, while 12-gauge wire is used for 20-amp circuits that power heavier loads. These sizes balance safety with cost and are easy for electricians to work with.

In small commercial spaces, 12 AWG is often the minimum, with 10 AWG sometimes used for higher-demand equipment. Outlets for tools, lighting systems and small appliances rely on these sizes to deliver consistent power. Choosing the right gauge ensures circuits meet both code requirements and real-world performance needs.

Read: Grounding vs. Bonding: What’s the Difference?

What Is Ampacity?

Ampacity is the safe current-carrying capacity of a wire, and it depends on factors like size, material and insulation type. Every ampacity chart lists these values so technicians know how many amps a conductor can handle without overheating. Using the chart correctly helps prevent failures and ensure circuits operate safely.

Number of amps a conductor can carry safely

Different wire sizes have standard current ratings that determine how much load they can handle without overheating. Knowing these limits is critical for choosing the right conductor for each circuit.

- 15 amps: Often paired with 14-gauge wire, this size is common in general lighting and outlet circuits.

- 20 amps: Usually requires 12-gauge wire and is often used for kitchen appliances or heavy-duty receptacles.

- 30 amps: Commonly matched with 10-gauge wire, this size supports larger equipment like dryers or small HVAC units.

These values are general guidelines, but they show how conductor size directly affects safe current capacity. Matching the right amp rating to the wire size is essential for both safety and code compliance.

Factors that affect ampacity

Several conditions can change how many amps a conductor can safely carry. A wire size chart often lists these adjustments, so technicians know when to modify their choices.

- Ambient temperature: Higher temperatures reduce how much current a wire can handle before overheating, which may require upsizing the conductor.

- Bundling of conductors: When multiple wires are run together, heat builds up, lowering their effective ampacity and altering what’s shown on the chart.

- Insulation type: Different insulation materials have different temperature ratings, directly impacting safe current capacity.

- Conductor material: Copper and aluminum carry current differently, which is why charts include separate ratings for each.

By accounting for these factors in a wire size chart, technicians can select conductors that perform safely under real-world conditions.

Read: Voltage Drop Test: What It Is and How to Do It

Wire Size for Common Circuits

15 amp, 20 amp and 30 amp

- 15 amps → often uses 14 AWG

- 20 amps → often uses 12 AWG

- 30 amps → often uses 10 AWG

Motor loads and consulting manufacturer specs

Motors often draw more current when starting than when running at full speed. This surge can put extra stress on wiring and protective devices if the circuit isn’t designed for it. That’s why general charts alone may not provide enough guidance.

Manufacturers publish specifications that list the exact current and protection requirements for their equipment. Following these specs helps ensure motors run efficiently and avoids voiding warranties. It also keeps the installation compliant with code and industry standards.

Read: Types of Electrical Circuits Explained

Copper vs. Aluminum Conductors

Pros, cons and terminations

Copper and aluminum are the two most common conductor materials. Each comes with clear strengths and trade-offs that affect performance and cost.

Pros

- Copper durability: Copper is highly conductive, resists corrosion and maintains stable connections over time.

- Aluminum affordability: Aluminum is lighter and less expensive, making it practical for long runs and large-scale projects.

Cons

- Copper cost: Copper is more expensive, which raises installation costs for large jobs.

- Aluminum expansion: Aluminum expands and contracts more with temperature changes, which can loosen connections if not managed.

Proper terminations are critical for both materials. Using the right lugs, connectors and anti-oxidant paste ensures safe, long-lasting connections.

Anti-oxidant paste and proper lugs for aluminum

When aluminum conductors are installed, they must be paired with anti-oxidant paste at connection points. This paste reduces the risk of corrosion, which can otherwise increase resistance and create hot spots. It’s a small step that makes a big difference in long-term reliability.

Proper fittings are just as important. Using lugs and connectors rated for aluminum helps ensure the conductor stays secure even as it expands and contracts with temperature changes. Together, these practices keep the system safe and code-compliant.

Read: Top Electrical Safety Tips for Beginners

Insulation, Temperature Ratings and Conduit Fill

THHN, THWN and other common markings

Letters printed on wire insulation are shorthand for important ratings. Codes like THHN or THWN tell technicians how the wire is designed to perform in certain environments. Without these markings, it would be difficult to confirm whether a conductor is safe for the job.

THHN, for example, is rated for dry locations and higher temperatures. THWN adds a water-resistant rating, making it acceptable for damp or wet conditions. These small differences in lettering change how and where the wire can be installed.

Understanding insulation markings helps avoid costly mistakes during installation. Choosing the wrong type can lead to overheating, early failure or code violations. Reading and applying these markings correctly is a core skill for any technician.

Ambient temperature, bundling and derating basics

Ambient temperature has a direct impact on conductor performance. When wires are exposed to heat, their ability to carry current safely decreases. This is why ratings in charts assume standard conditions unless otherwise noted.

Bundling conductors together can also reduce their ampacity. Multiple wires in a single conduit trap heat, which raises operating temperatures and increases resistance. Derating factors account for this effect to keep systems within safe limits.

Derating is the process of adjusting ampacity values to reflect real-world conditions like temperature and bundling. By applying these corrections, technicians ensure circuits don’t overheat and remain compliant with code. Ignoring derating can lead to premature equipment failure and safety hazards.

Read: Series vs. Parallel Circuits: What Future Electrical Technicians Need to Know

Voltage Drop Basics

Long runs, conductor resistance and upsizing

The longer a wire run is, the more resistance it creates in the circuit. This resistance reduces the amount of voltage available at the load end, which can impact performance. Sensitive equipment like motors or electronics may struggle under these conditions.

Conductor resistance isn’t just about length — it’s also about size and material. Smaller wires and materials with higher resistance lose more voltage over distance. Understanding this relationship helps technicians plan circuits that stay efficient.

One common solution is upsizing the conductor. By using a larger wire, resistance is reduced, and more voltage reaches the equipment. Upsizing is a practical way to maintain efficiency on long runs and prevent costly issues.

Simple rules of thumb and when to do the math

Technicians often use quick guidelines to estimate voltage drop and conductor performance, but some situations call for precise calculations. Knowing when to rely on simple rules and when to run the numbers ensures circuits remain safe and efficient.

Rules of thumb

- 100-foot rule: If a run exceeds 100 feet, check for potential voltage loss.

- 3% guideline: Keep voltage drop under 3% for branch circuits to avoid noticeable performance issues.

- One size up: For long runs of sensitive loads, increase conductor size by one gauge as a precaution.

- Appliance sensitivity: Motors and electronics often need stricter drop limits than lighting circuits.

- Check connections: Even with proper wire size, loose or corroded terminations can cause extra drop.

When to do the math

- Critical systems: Life safety equipment or sensitive electronics demand exact calculations.

- Borderline runs: When a circuit is close to code limits, precise math verifies compliance.

- Mixed materials: Using both copper and aluminum in the same system requires calculation for accuracy.

- High current loads: Large motors, HVAC systems or welders often exceed what rules of thumb can cover.

- Unusual conditions: Elevated ambient temperatures or bundled conductors require derating math.

Using rules of thumb can save time, but detailed calculations provide the certainty needed for safety and inspections.

Read: How Electrical Safety Systems Protect Modern Technicians

Safety and Code Considerations

Conductor limits on breaker sizing

Circuit breakers are designed to protect wires from carrying more current than they can handle. If a breaker is rated higher than the conductor’s ampacity, the wire may overheat before the breaker trips. This creates a serious fire and safety risk.

Matching breaker size to conductor limits ensures protective devices work as intended. Technicians also consider code rules and derating factors to choose the correct breaker. Getting this step right helps keep circuits safe and compliant.

Local codes and inspector guidance

While the National Electrical Code (NEC) sets national standards, local codes may include additional requirements. Inspectors use these rules to judge whether an installation is safe and acceptable. Overlooking them can lead to rework or failed approvals.

Inspector guidance also helps clarify gray areas in the code. They may require extra labeling, documentation or specific materials to meet local expectations. Following their direction can ensure smoother projects and safer systems.

Read: Electrical Technician Career Pathways: What Comes After Graduation

Learn How To Read Wire Gauge Charts at Universal Technical Institute

At Universal Technical Institute, students can choose from four electrical training options: wind energy, robotics and automation, industrial maintenance or electronics. No matter the path chosen, they can develop key skills needed for electrical work after graduation, including wire gauge chart reading, circuit testing and equipment connection.1

Hands-on labs for measurement, terminations and troubleshooting

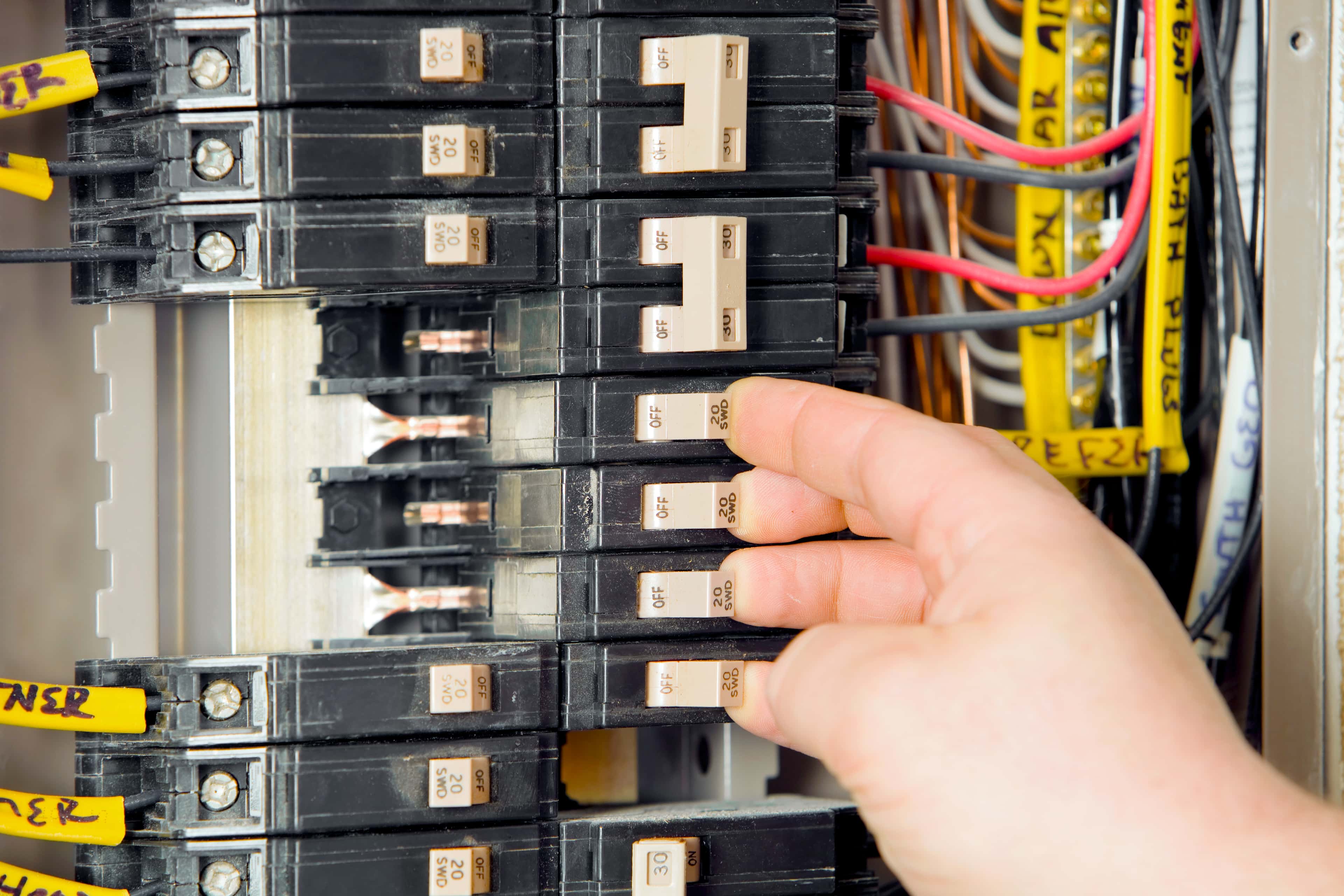

In labs at Universal Technical Institute, students train directly with live panels and real-world components. They use test meters, hand tools and industry-aligned equipment to practice the same tasks technicians perform in the field. This approach helps build confidence and accuracy.

Students also learn to make proper terminations, from tightening lugs to securing splices. These details are critical for safety and reliability, and practicing them on real equipment can make the skills second nature. Mistakes can be corrected in the lab so they don’t happen on the job.

Chart reading is only part of the process. Instead of just studying a wire gauge chart, students apply it in live scenarios to select the correct wire size, connect circuits and troubleshoot issues. This hands-on practice helps them understand how theory translates into daily work.

Career-ready skills in one year or less

In one year or less, students can practice in-demand skills on real systems and prepare for entry-level roles in the field. No matter the training path they choose, they can graduate with practical skills that help them pursue the workforce with confidence.

Electrical Training for Skills in Wire Gauge Chart Reading and More!

Wiring isn’t just about charts — it’s about building in-demand skills that power entire industries. By training in any of our four electrical training programs, you can develop hands-on career skills in one year or less.

If you’re ready to move forward, dial 1-800-834-7308 or click the button below to request more information. An Admissions Representative will reach out to answer your questions and help identify which electrical training program is the best fit. Enroll now if you’re ready to get started ASAP.

Universal Technical Institute of Illinois, Inc. is approved by the Division of Private Business and Vocational Schools of the Illinois Board of Higher Education.