If you're thinking about a future in welding but wondering whether math is part of the job, you're not alone. Many aspiring welders ask, “Does welding require math?” The short answer is yes, but not the kind that requires a calculator and a textbook every day.

Welders rely on practical math skills to read blueprints, measure materials, adjust machine settings and ensure precision in every project. At Universal Technical Institute (UTI), math is built right into the hands-on training you’ll get in the Welding Technology program, making it easier to understand and apply in real welding projects.1

In this guide, we’ll explore why math matters in welding, the types of math welders use daily and how UTI helps students build the confidence they need for this essential trade.

Why Math Is Important in Welding

Math may not always be the first thing that comes to mind when considering a welding career, but it’s a critical skill for welders. Whether you’re adjusting machine settings, calculating material dimensions or measuring angles, welding math ensures accuracy and precision in every task. From the initial cut to the final weld, math plays an integral role in making sure the job is done right.

Inaccurate measurements can lead to wasted materials, structural failures or even safety hazards. The ability to perform basic welding math and apply it to real-world scenarios is essential for achieving strong, high-quality welds that meet industry standards. So, does welding require math? Absolute precision and accuracy are extremely important, and math helps produce higher-quality welds.

Types of Math Welders Use

While you don’t need to be a math expert to be a welder, understanding certain types of math is essential. Welders use a variety of mathematical concepts daily, from basic geometry to more complex algebra and trigonometry. Here’s a breakdown of the core math skills that welders rely on to complete their jobs effectively:

Fractions and decimals

Reading and interpreting measurements is a fundamental part of welding, especially when working with dimensions in inches or millimeters. Welding math, particularly fractions and decimals, is necessary when calculating lengths, thicknesses, tolerances and fitting metal pieces together. Accurate calculations ensure that each cut and weld fits precisely into the overall design.

Geometry and angles

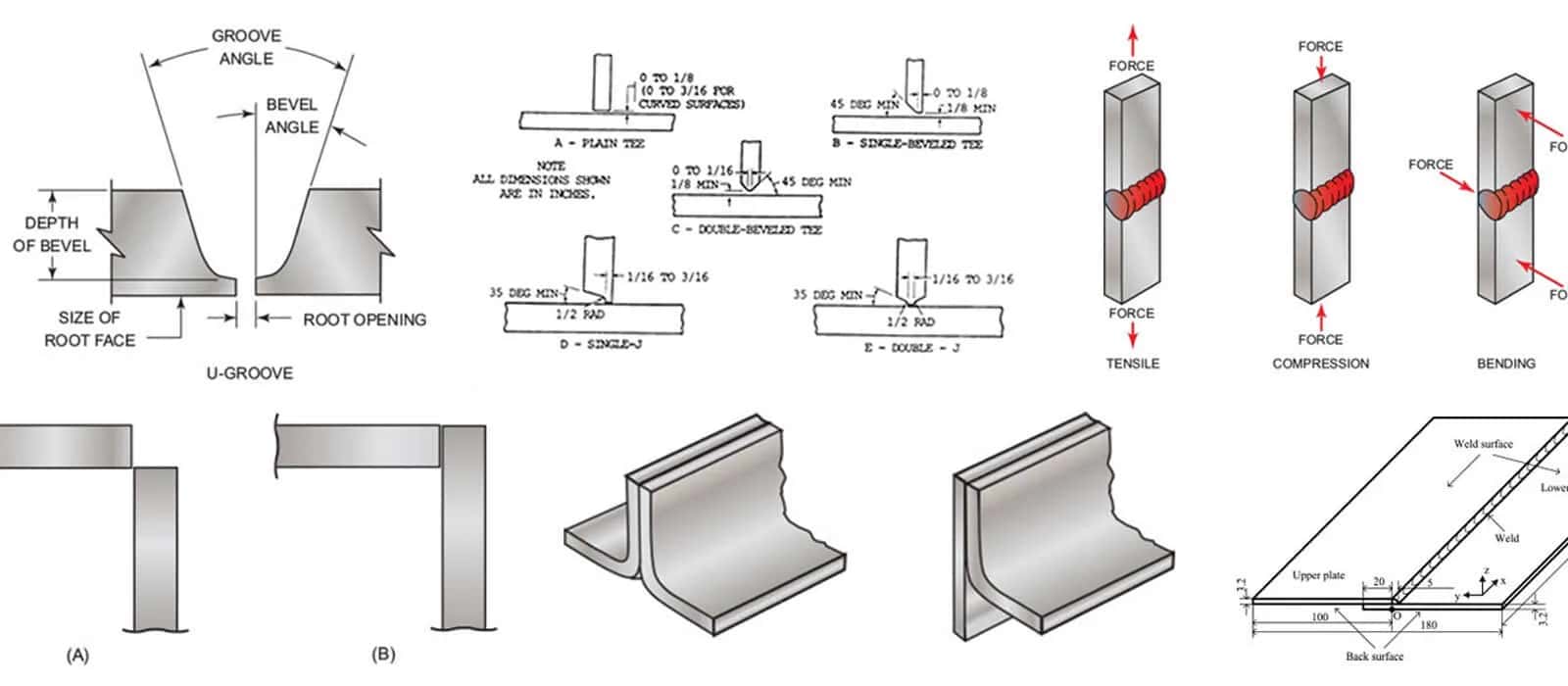

Welders frequently work with blueprints and layouts that require knowledge of angles and shapes. Geometry helps determine how materials should be cut and joined, especially when dealing with pipefitting or structural welding.

Basic algebra

Algebra is commonly used in welding to calculate factors like heat input, force or gas flow rates. Welders use algebraic formulas to calculate how various factors, such as amperage or voltage, impact the weld. This is particularly important for more advanced welding techniques, where adjustments need to be precise to ensure the best results.

Real-World Examples of Welding Math in Action

Welding math isn’t just theoretical — it’s used daily on the job site. Here are a few real-world examples where welding math plays a crucial role in achieving successful outcomes:

Machine settings

Before starting any weld, a welder must adjust their machine based on the material type and thickness. This involves setting the proper amperage, voltage and wire speed — key aspects of welding math. These settings are determined by performing calculations that take into account the material’s properties and the specific welding method being used.

Calculating material cost or usage

Welders also need to calculate how much material they will need for a project. Whether estimating metal, filler material or shielding gas, having a solid understanding of welding math helps ensure that the correct amount of materials is ordered. By doing so, welders can prevent waste, stay within budget and optimize project efficiency. UTI’s welding courses, like WELD-105: Engineering and Fabrication, teach students how to estimate material needs for welding projects. This includes calculating the amount of metal, filler material and shielding gas required. Understanding these calculations helps welders minimize waste, control costs and improve overall project efficiency.

How Welding Schools Teach Math

At UTI, math isn’t just something you learn in a classroom, it’s incorporated into your hands-on welding training. Students apply welding math directly in labs, where they learn how to measure, cut, fit and weld in real scenarios. This practical approach helps them understand the "why" behind the math and how it directly impacts their welding projects.

UTI instructors break down concepts in ways that are easy to understand, using real-world examples and industry-standard tools. As students complete shop projects and practice labs, they see how math directly applies to their welds, reinforcing its importance in welding.

Read: Types of Courses at Welding School

Start Your Welding Journey With Confidence

While welding does require math, it’s nothing to worry about when you have the right training. At UTI, you’ll learn the essential math for welders in the context of hands-on welding projects. The program equips students with the knowledge and skills needed to navigate welding math with confidence.

With experienced instructors, a curriculum aligned with industry standards and hands-on training, UTI can give you the tools to succeed in the welding industry.1 Request more info to get started on your welding journey! If you're ready to take the next step, you can fill out an application and begin building the skills you need to pursue a career in welding.

Universal Technical Institute of Illinois, Inc. is approved by the Division of Private Business and Vocational Schools of the Illinois Board of Higher Education.