About the CNC Machining Technology Program

Craft sophisticated performance parts and components from raw materials. The CNC Machining Technology program provides the hands-on training and high-tech skills needed to prepare for a career as a computer numerical control (CNC) machinist after graduating.1

36 weeks

1 campus

What You’ll Learn in UTI’s CNC Machining Program

UTI’s CNC Machining Technology program focuses on building practical skills used in modern manufacturing. Coursework progresses from manual machining fundamentals to more advanced CNC applications, supporting students pursuing CNC machinist training and entry-level roles after graduation.

Throughout the CNC machinist training program, students may learn skills related to:

- Manual machining fundamentals and basic machine shop practices.

- Manual lathe and mill operations.

- Math, materials and measurements used in machining.

- CNC machining basics, including setup and operation.

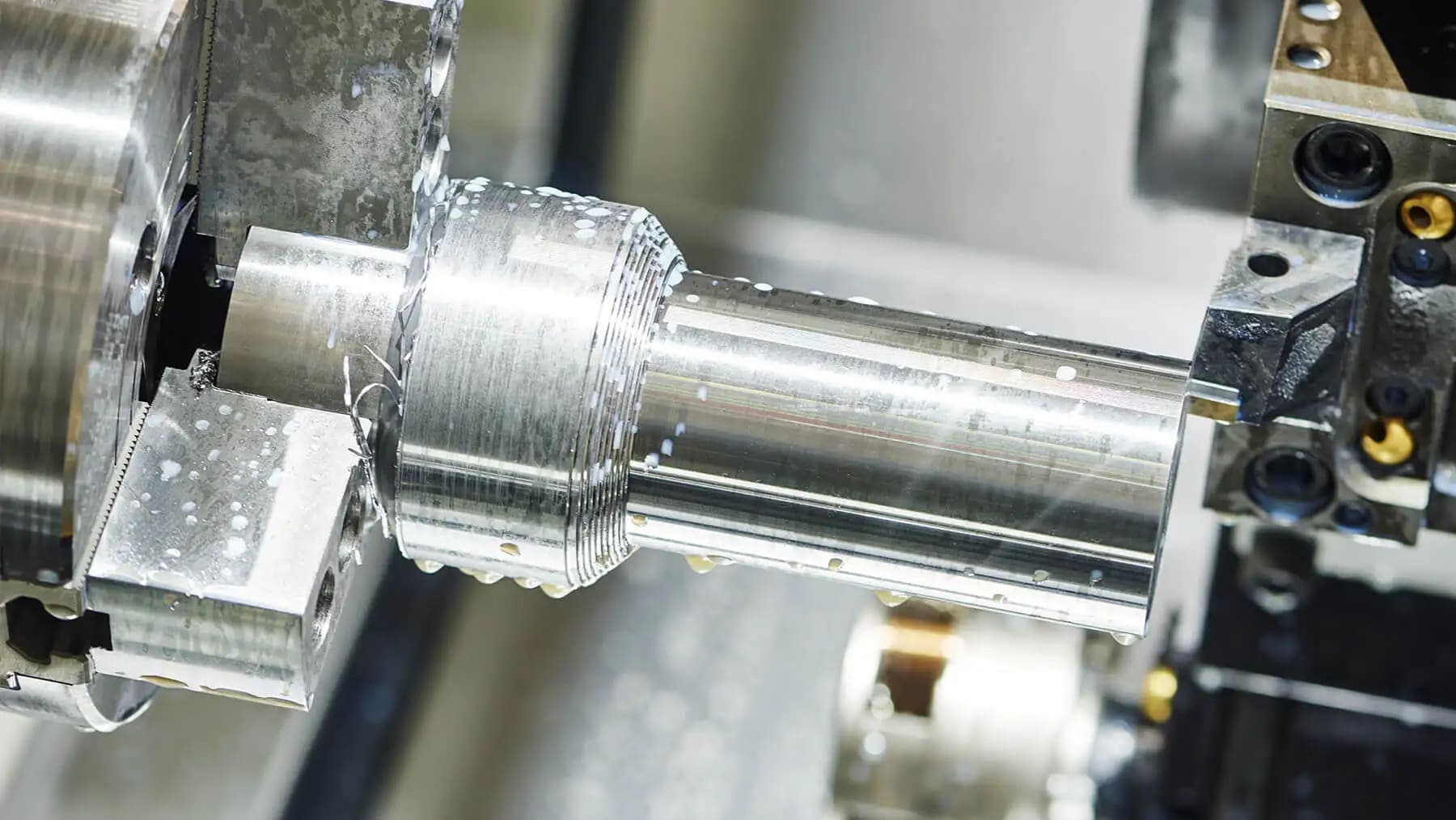

- CNC turning and milling processes.

- Introductory CAD and CAM applications.

- Multi-axis machining concepts, depending on course selection.

This structured approach helps students understand how CNC machining works and how machines, tools and software are used together in real-world shop environments.

After graduation, students will have the knowledge needed to pursue additional CNC-related certifications, which can help demonstrate technical skills to employers, depending on career goals and industry requirements.

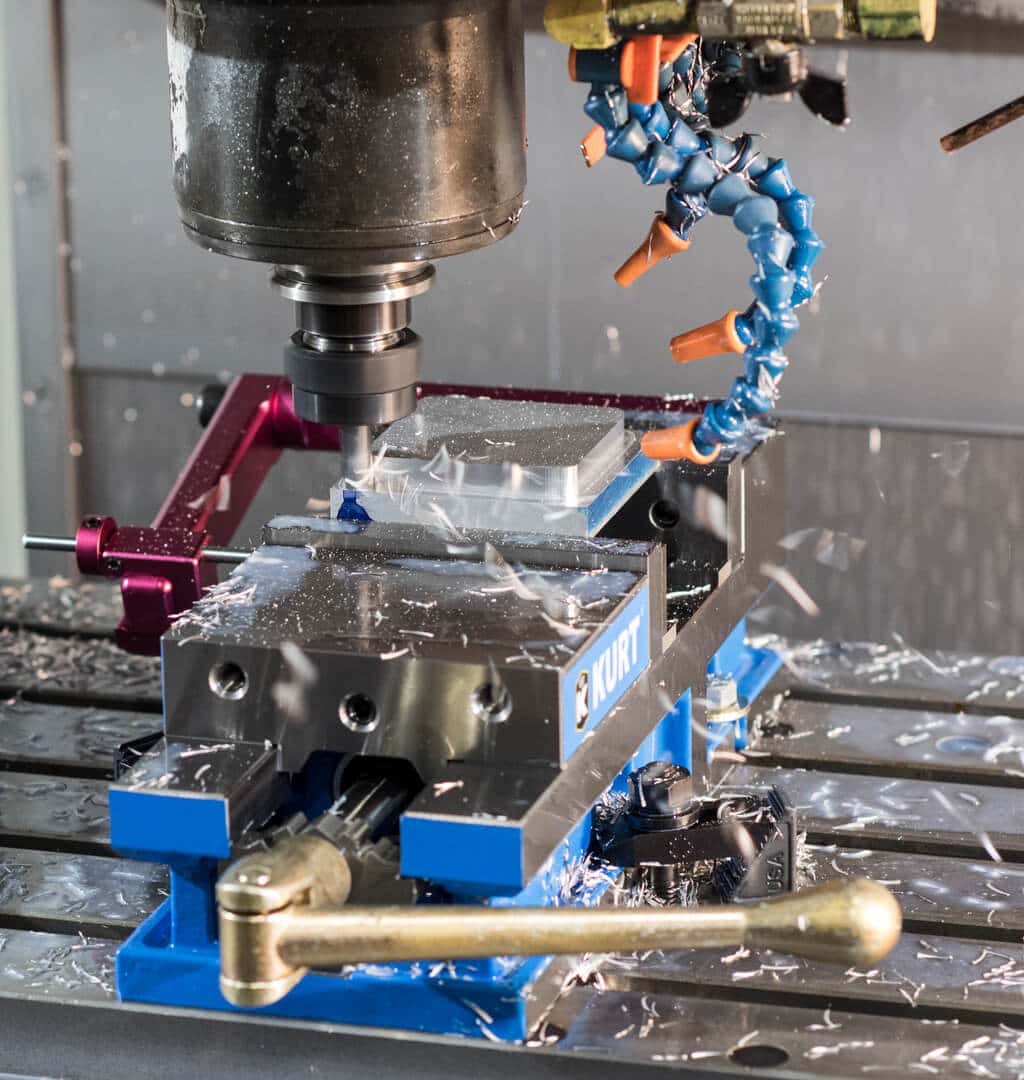

State-of-the-Industry Tools & Technology for Students

UTI’s CNC Machining Technology program uses industry-preferred tools and technology, allowing students to train on equipment similar to what’s used in professional shops. Students may learn with brands such as Mastercam, Mitsubishi Materials and Mitee-Bite, building familiarity with common CNC software and tooling.

Hands-on lab time allows students to practice setting up and operating CNC mills and lathes in a learning environment that emphasizes accuracy, safety and repeatability.

UTI CNC Machinist School Locations

The CNC Machinist Training program is available at our campus in Mooresville, North Carolina.

FAQs

Yes! As a student in the CNC program, you’ll have the opportunity to train with industry-preferred tools and technology from brands like Mastercam,Mitsubishi Materials and Mitee-Bite.

UTI’s CNC Machining program is designed to be completed in just 36 weeks. Explore our CNC machining courses here.

The median annual salary for computer numerically controlled tool operators in the United States was $49,970 in May 2024,34 according to the Bureau of Labor Statistics (BLS). This means half of CNC machinists earned more and half earned less. Keep in mind that salary depends on several factors, including experience, employer, demand and cost of living in the area. Learn more in our CNC machinist salary guide.

Graduates of UTI's CNC machinist training program are qualified for entry-level roles such as CNC machinist, CNC operator, machine technician or manufacturing support technician.77 Job titles and responsibilities can vary by employer and industry.

No prior machining or manufacturing experience is required. The CNC machinist training program is designed to introduce core concepts step by step, making it accessible for those new to CNC machining as well as career changers exploring the field.